Hanna Shibata

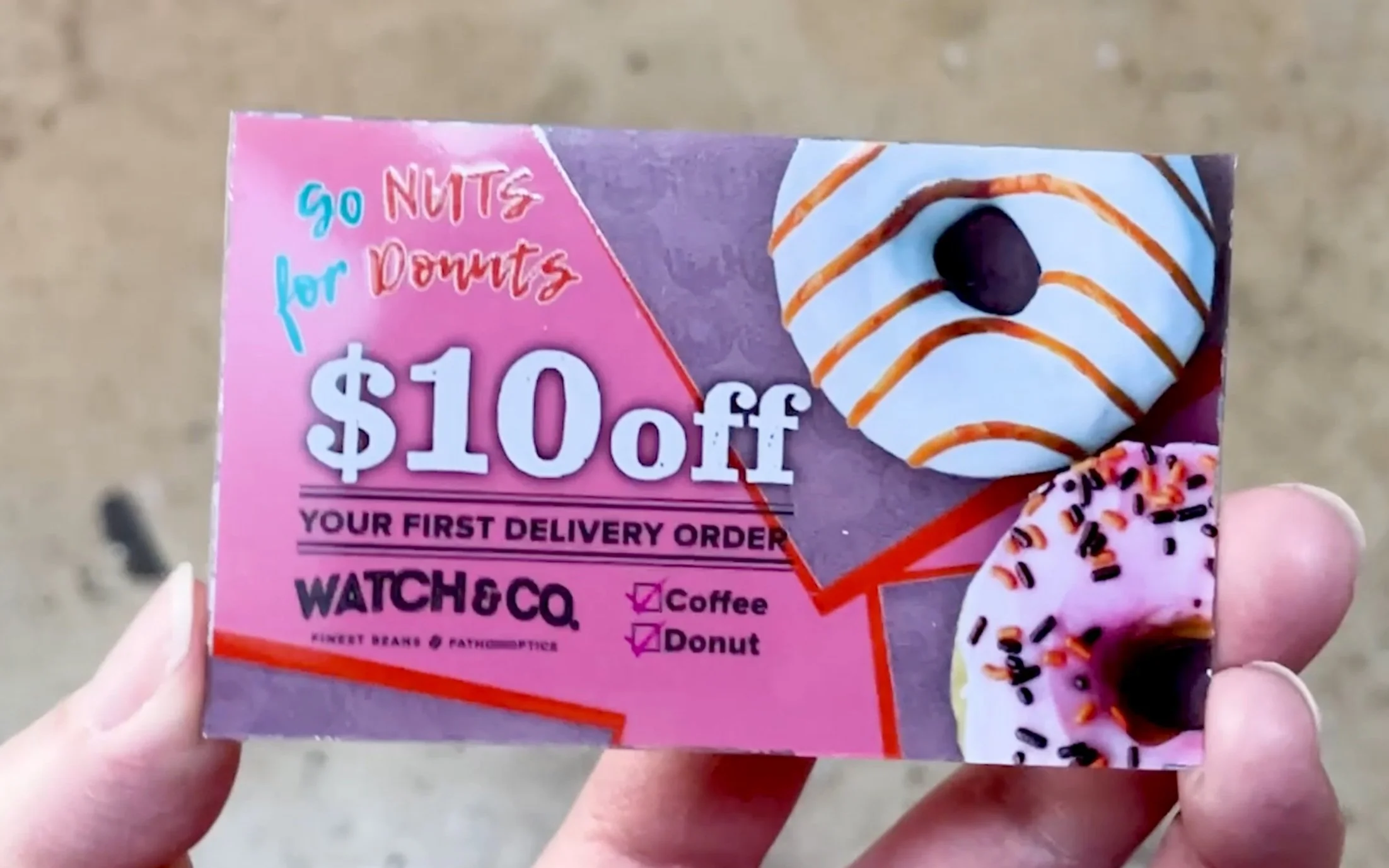

Why do people give gift cards? They’re more thoughtful than money and more practical than wrapping the actual goods you’d purchase, if it’s hot coffee and donuts. So you see a variety of themed and embellished gift cards to improve the gifting experience and to stand out at the point of sale. But these require a steady stream of fresh designs to stand out.

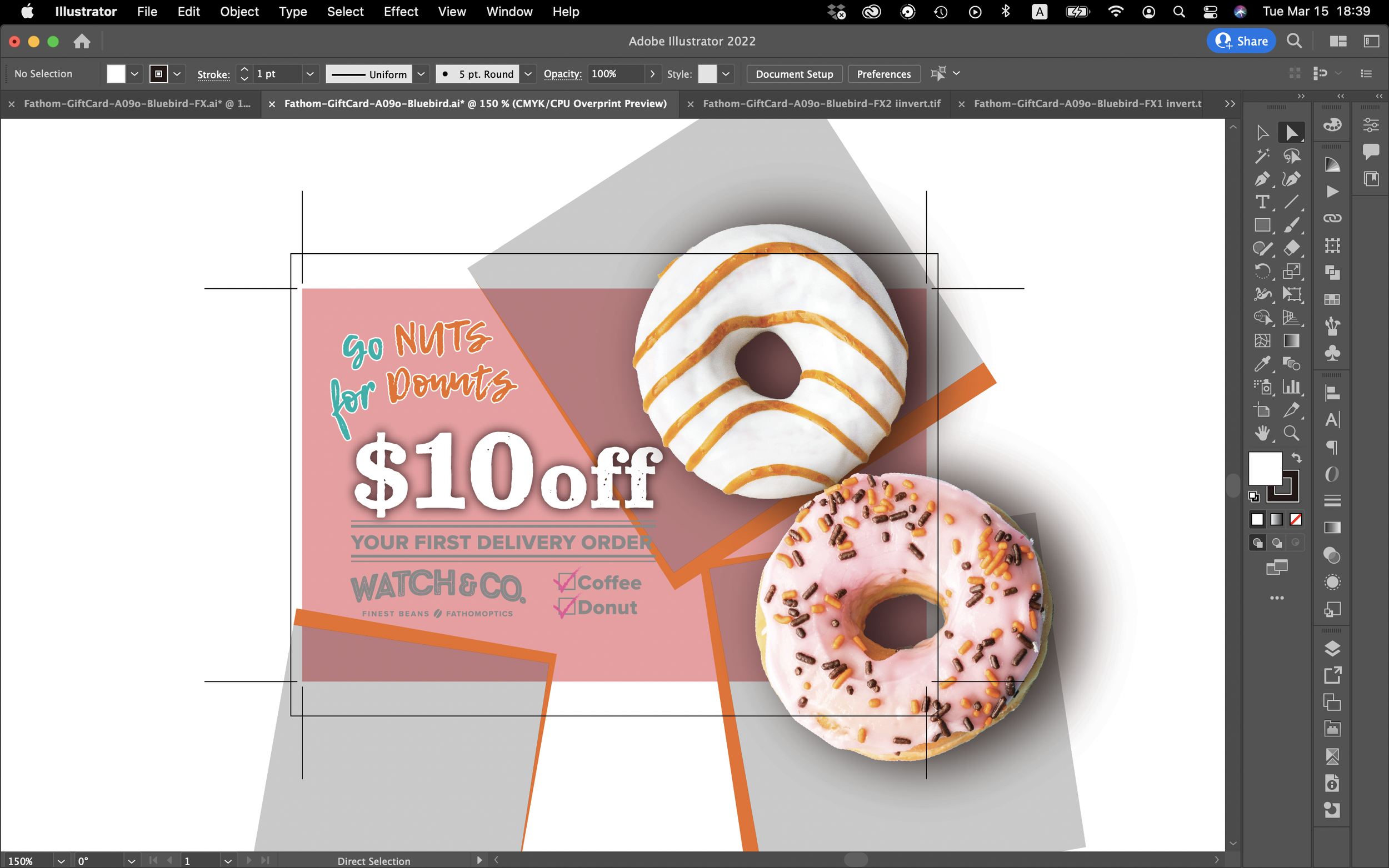

Fathom Effects are a quick way to give brands a boost. Designers can drop existing design files into Fathom Designer and add motion and depth effects wherever there’s a spot color. Among other things, our embellishments can achieve the glitter of foil even at the prototyping stage because they’re ink-based. With a high-quality printer, what you see is what you’ll get in production—and as a bonus you won’t have the waste of foils. I wanted to experiment with the immediate prototyping and iteration process to add promotional material to an existing brand.

Our embellishments can achieve the glitter of foil even at the prototyping stage because they’re ink-based.

Product Brief

Watch & Co. is a brand introducing casual coffee drinkers to premium beans with casual experiences. How can Fathom contribute to the brand’s expansion with a minimum of effort? Let’s find out with a case study.

We recently befriended our neighbor, Bluebird Graphic Solutions, who helps experiential graphic designers create beautiful signs and architectural elements. I used their Mimaki machine to test quick iterations of a gift card.

Process

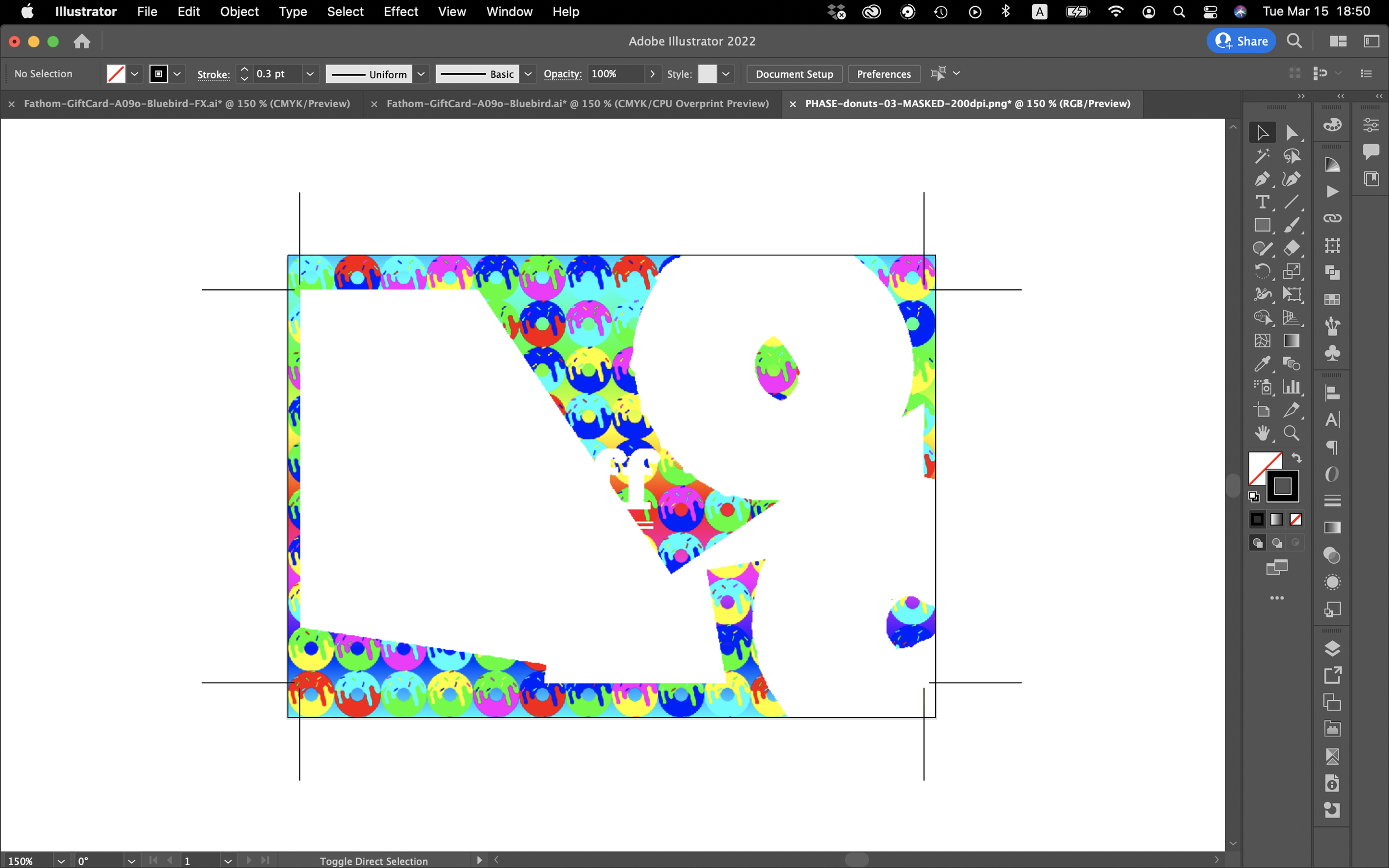

After trying out three different Fathom effects, I decided to move forward with the flashy Donuts effect, starting another cycle of design iteration using Fathom Designer and the 3D viewer.

Prototyping

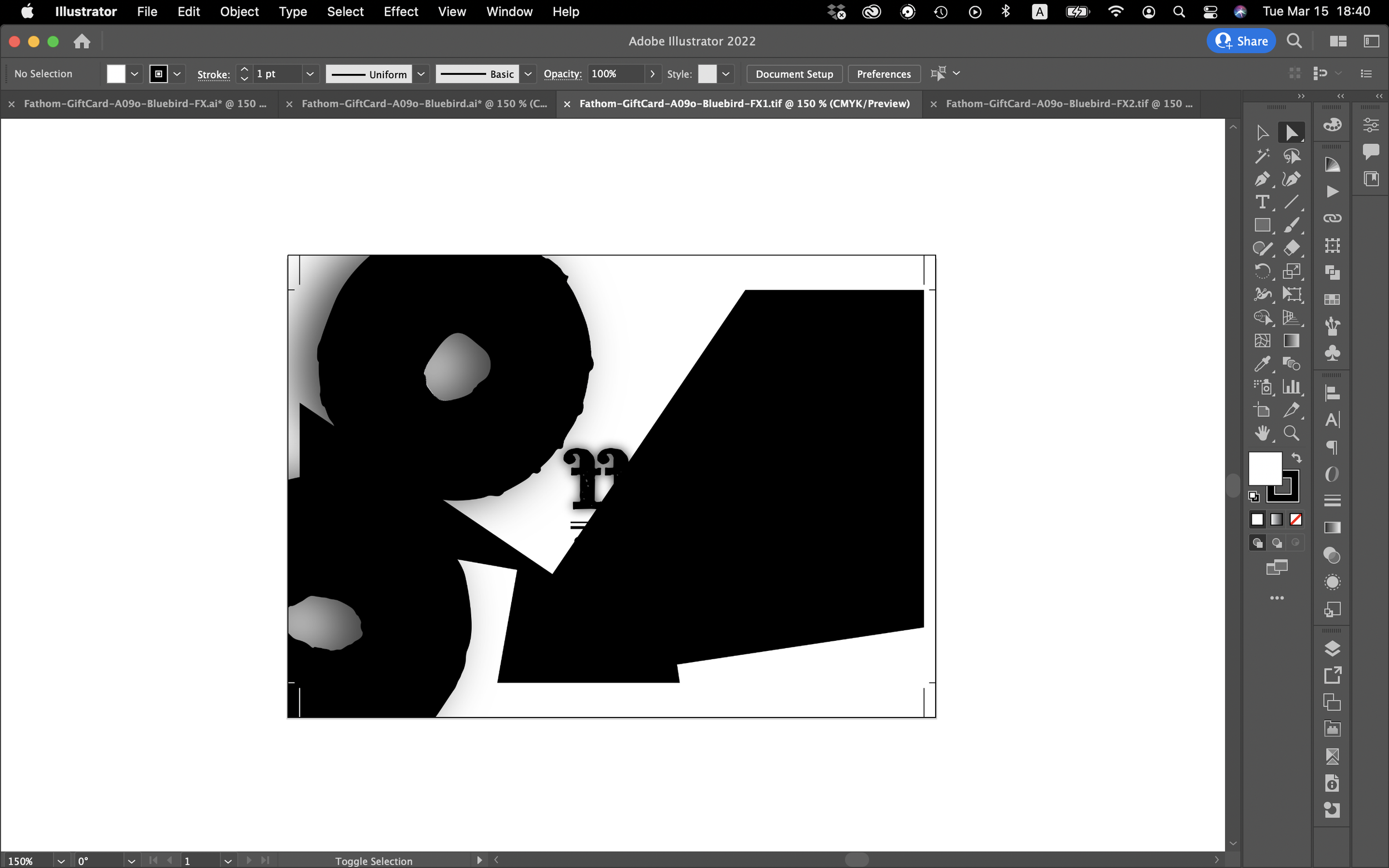

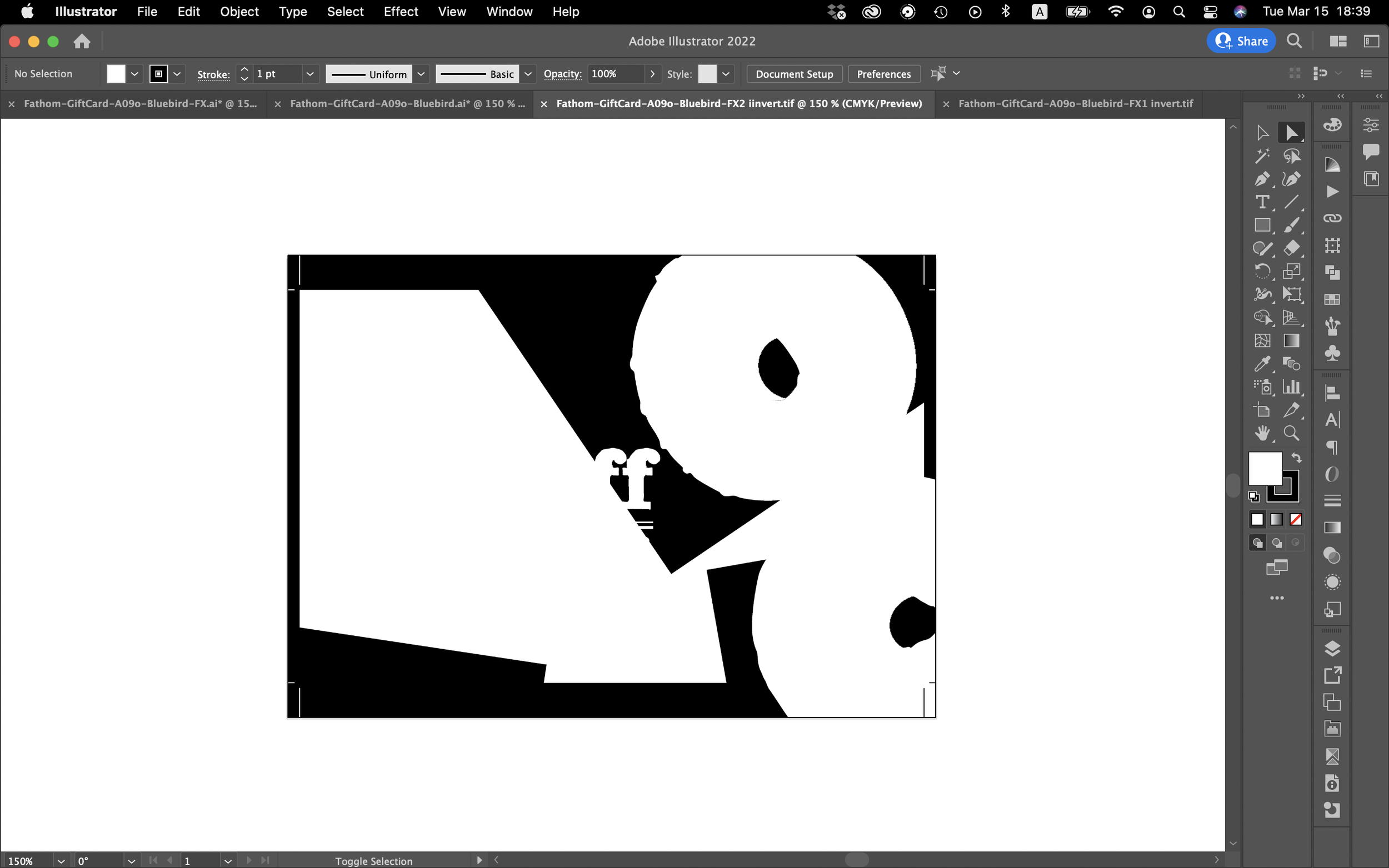

Since Fathom Effects are a layer of overprint and black and white ink that create the effect, I prepared the files as following:

Conclusion

Since Fathom Effects can be printed only with ink on a sufficiently high resolution printer, it’s easy to start prototyping. I’m looking forward to doing another round using the same, or similar, materials for the final product.